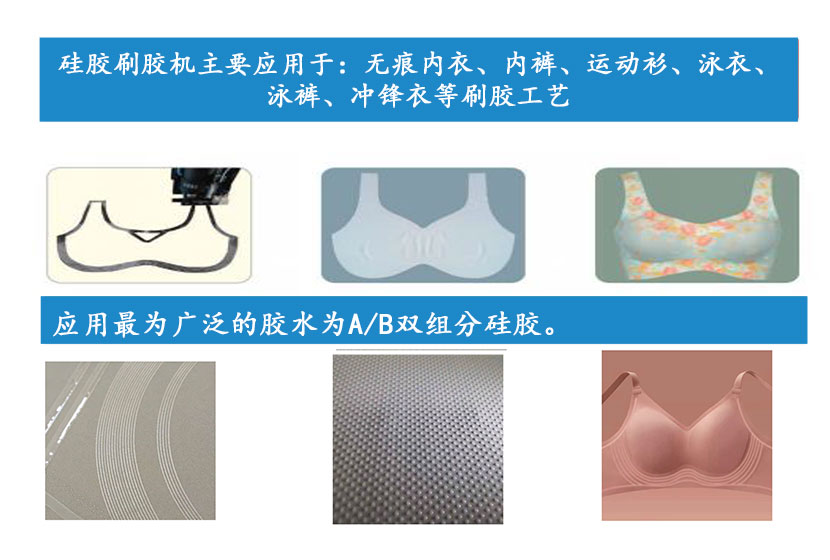

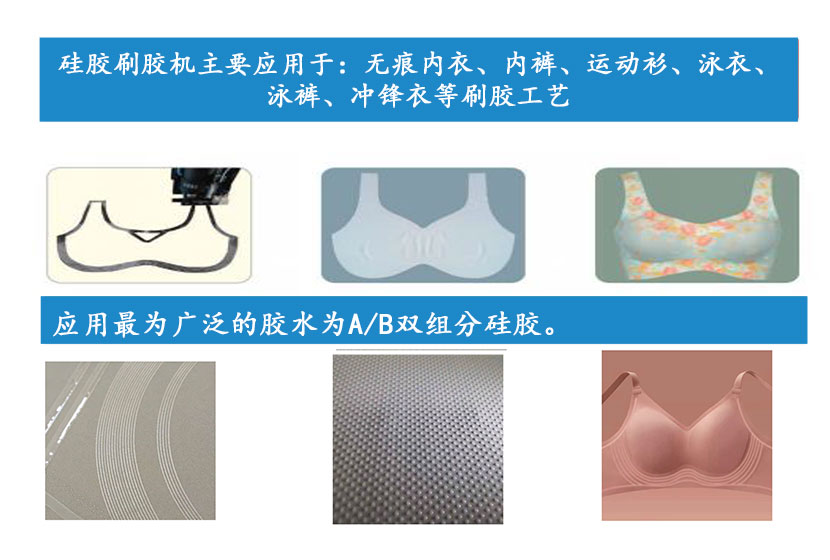

Product details

1: Automatic cycle work greatly improves production efficiency, with a daily output of approximately 5000 pieces.

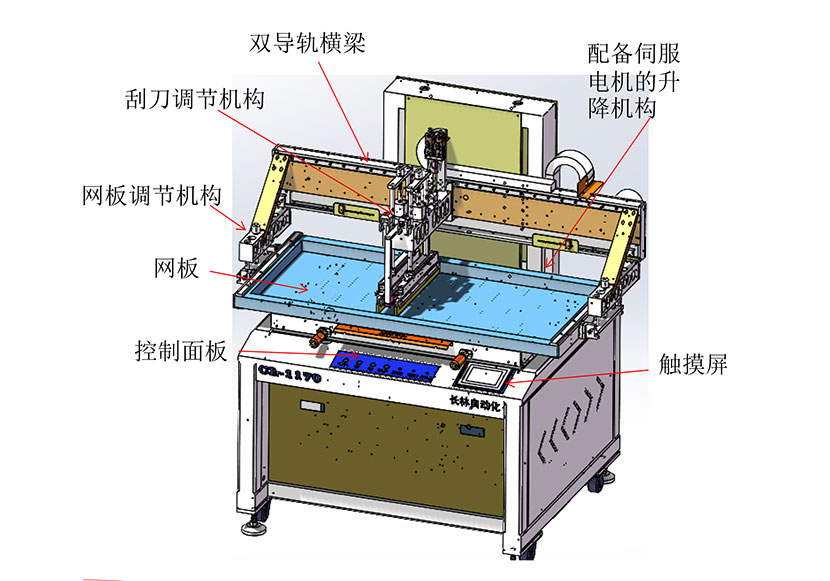

2: Fast brushing speed, uniform lines, stable operation, capable of completing various shapes of graphics and lines.

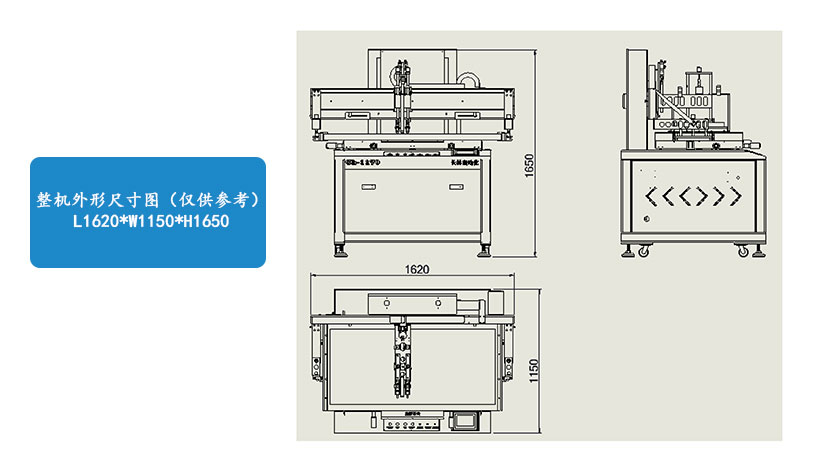

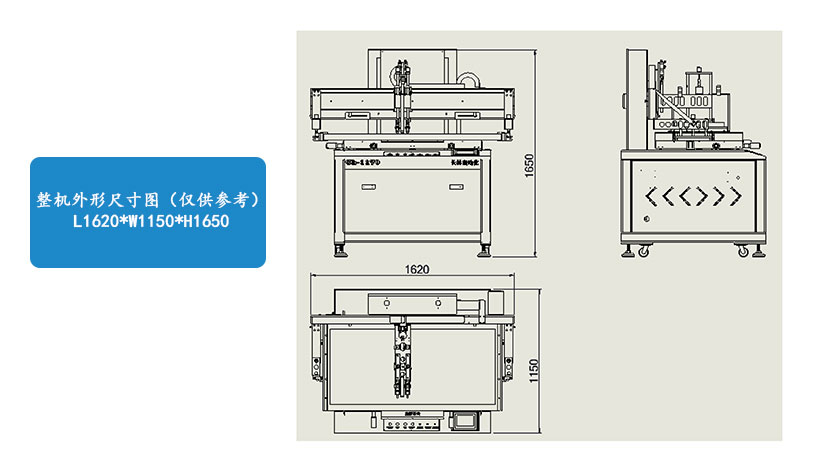

3: Suitable for mesh panels with a length of 1200-1400mm, the workbench size is 1100X700mm (expandable to 1300mm), and the maximum height that the mesh panel can lift is 260mm.

4: The size and thickness of the lines can be made into mesh plates according to graphic requirements, fully meeting various shapes.

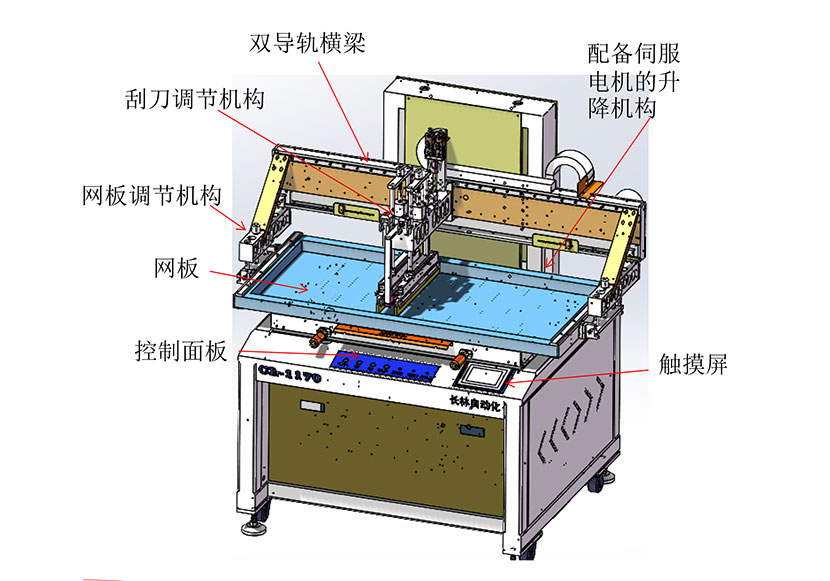

5: It can be equipped with a professional glue pressing system to achieve automatic glue supply.

6: Save workspace, reduce labor costs, and improve efficiency and quality.

7: Equipped with a professionally designed suction platform, it avoids the inconvenience of traditional methods of fixing the cutting pieces with platform adhesive.

8: The unique intelligent control system makes the glue brushing machine operate more intelligently and stably.

Equipment model: CL-1170

External dimensions: L1620 * W1150 * H1650

Working range: X: 1300mm Y: 700mm Z: 260mm

Glue dispensing accuracy: ± 1%

Maximum speed: 1000mm/s

Equipment weight: 350Kg

Control method: 7-inch touch screen+switch button

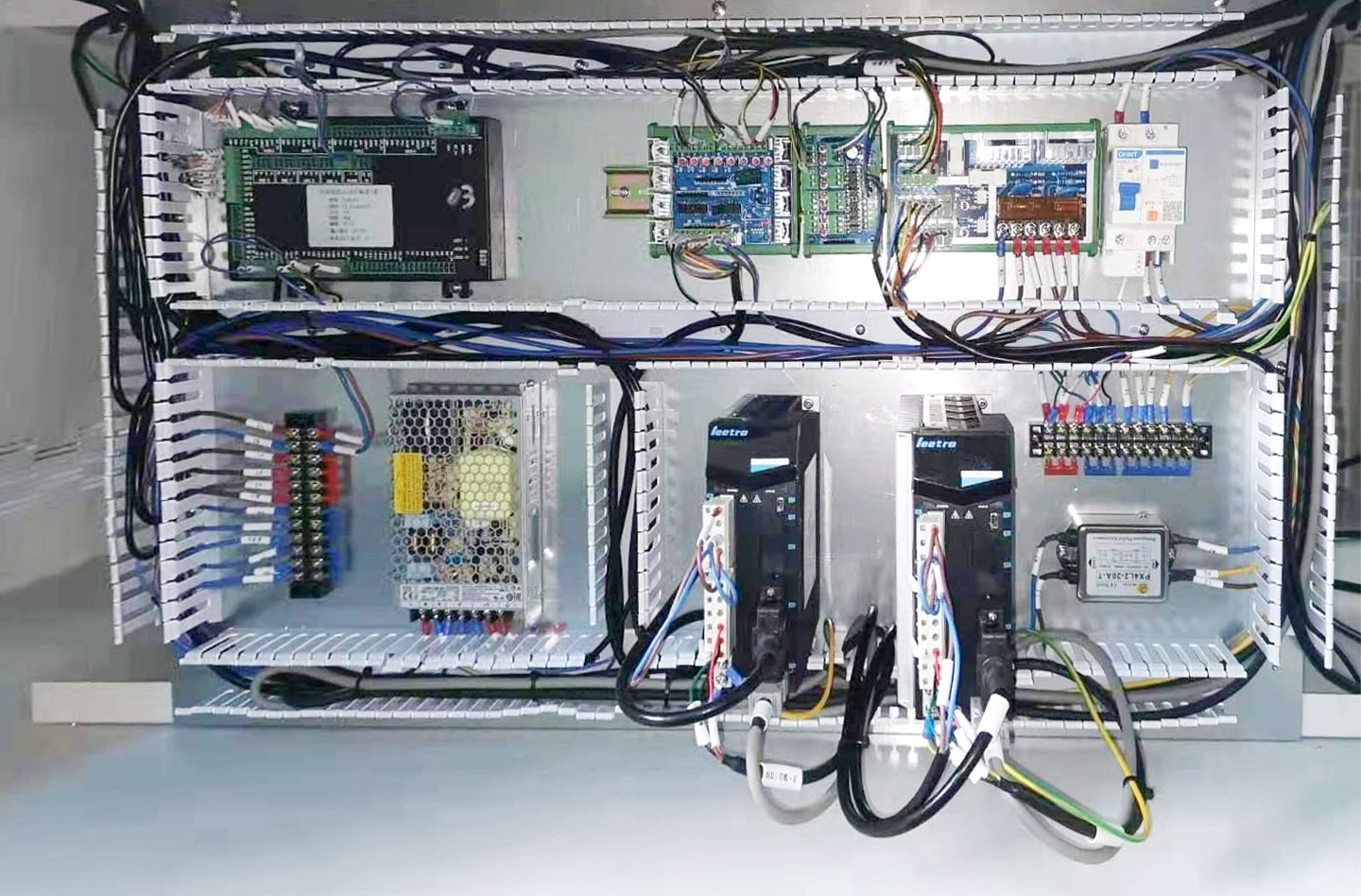

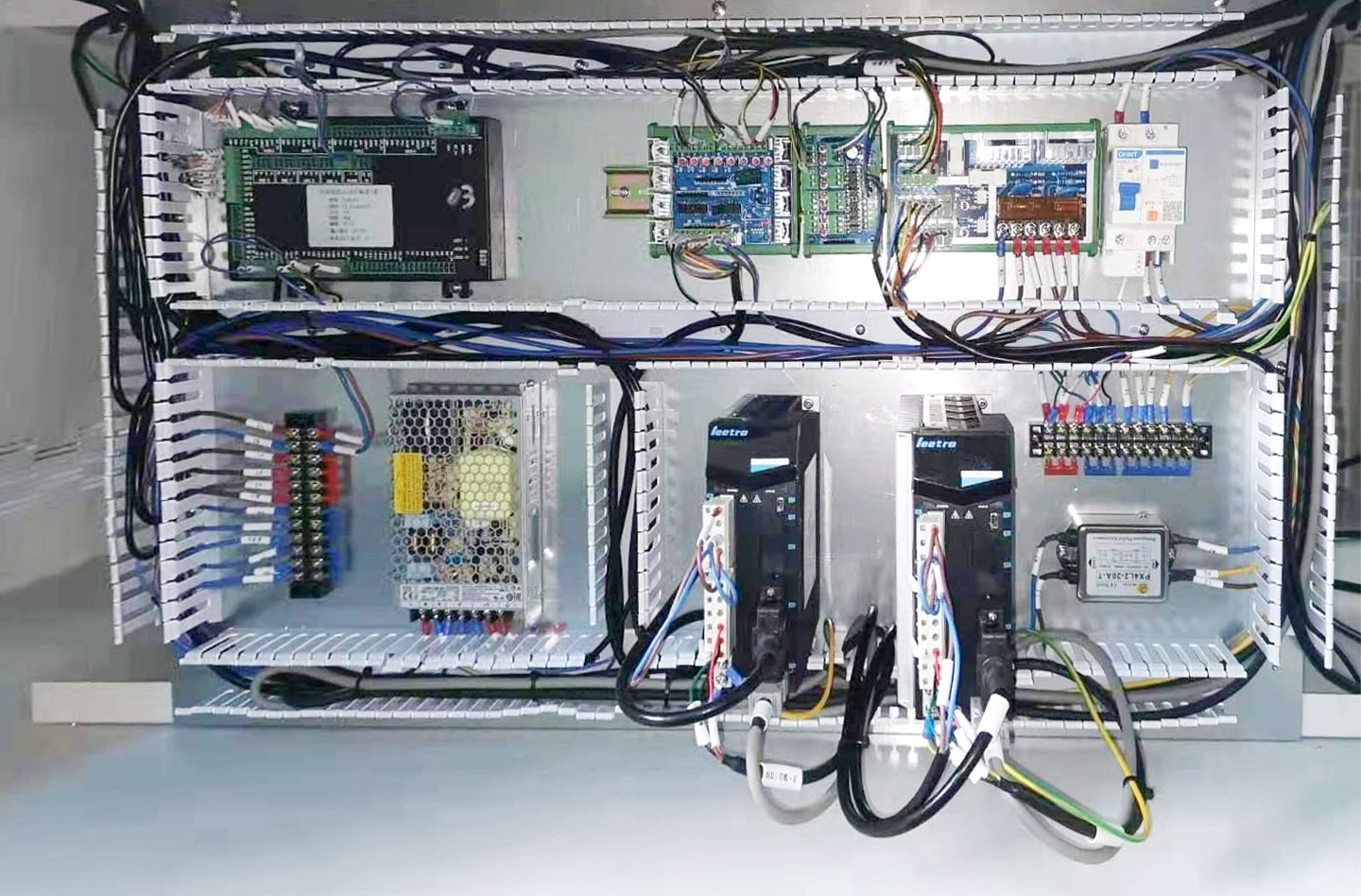

Transmission method: 2-axis (servo motor+belt linear module)

Repetitive accuracy: ± 0.03mm

Glue supply method: manual or automatic glue supply

Working air pressure: 6.0 ± 0.5Kg/cm ^ 2

Gas consumption: -100/min

Operating platform height: 810mm ± 25mm

Base platform: industrial marble

Working voltage: AC220V 50HZ

Working environment: 0 ℃ -40 ℃

Operating power: 2.5KW

Drive system: Lechuang/Leisai servo motor

Pneumatic components: Yadeke

Sensor component: Omron